In today’s rapidly evolving industrial landscape, Nexa Automation stands at the forefront of delivering high-quality industrial solutions. Whether you’re managing a factory, a production line, or an automated system, understanding PLCs, VFDs, and smart electrical components is essential for optimizing efficiency, reducing downtime, and enhancing overall productivity. This article provides a detailed overview of these components, their uses, benefits, and how integrating them can transform your industrial operations.

What is a PLC (Programmable Logic Controller)?

A Programmable Logic Controller (PLC) is the backbone of modern automation. It is an industrial computer designed to monitor inputs, make decisions, and control outputs in real-time. In simple terms, a PLC acts as the "brain" of machines and production lines.

Key Functions of PLCs

- Automation Control: PLCs replace manual switches and relays, executing complex tasks automatically.

- Data Collection: They gather information from sensors, motors, and devices for monitoring and analysis.

- Reliability: Built for harsh industrial environments, PLCs ensure consistent operation without interruptions.

- Flexibility: Easily programmable to adjust to new processes or machines.

For example, in a bottling plant, a PLC can manage conveyor belts, sensors, and filling machines simultaneously, ensuring smooth operation and minimal errors.

Synonyms/Related terms: industrial controller, automation controller, machine controller.

Understanding VFDs (Variable Frequency Drives)

Variable Frequency Drives, commonly known as VFDs, are crucial for controlling the speed and torque of electric motors. By adjusting the frequency and voltage supplied to motors, VFDs help optimize energy usage and improve motor performance.

Advantages of Using VFDs

- Energy Efficiency: Reduce electricity consumption by controlling motor speed according to demand.

- Extended Equipment Life: Smooth start and stop mechanisms reduce mechanical stress.

- Process Precision: Maintain accurate control over production processes, ensuring consistent output.

In combination with PLCs, VFDs can significantly enhance factory automation. For instance, a water treatment facility can regulate pump speeds efficiently, reducing energy costs and improving system reliability.

Synonyms/Related terms: variable speed drive, motor controller, frequency inverter.

Smart Electrical Components: The Future of Industry

Smart electrical components go beyond traditional devices. These include sensors, relays, smart switches, and IoT-enabled devices designed to communicate and adapt to dynamic conditions. Integrating these components into industrial systems ensures real-time monitoring, predictive maintenance, and higher efficiency.

Key Features

- Connectivity: IoT-enabled components allow remote monitoring and control.

- Automation Integration: Easily compatible with PLCs and VFDs for streamlined processes.

- Predictive Maintenance: Alerts operators before failures occur, reducing downtime.

- Energy Management: Helps industries optimize electricity usage and reduce costs.

By using smart components, factories can achieve a fully connected ecosystem where machines, sensors, and control systems interact seamlessly, paving the way for Industry 4.0.

Synonyms/Related terms: intelligent electrical devices, automated electrical components, smart industrial modules.

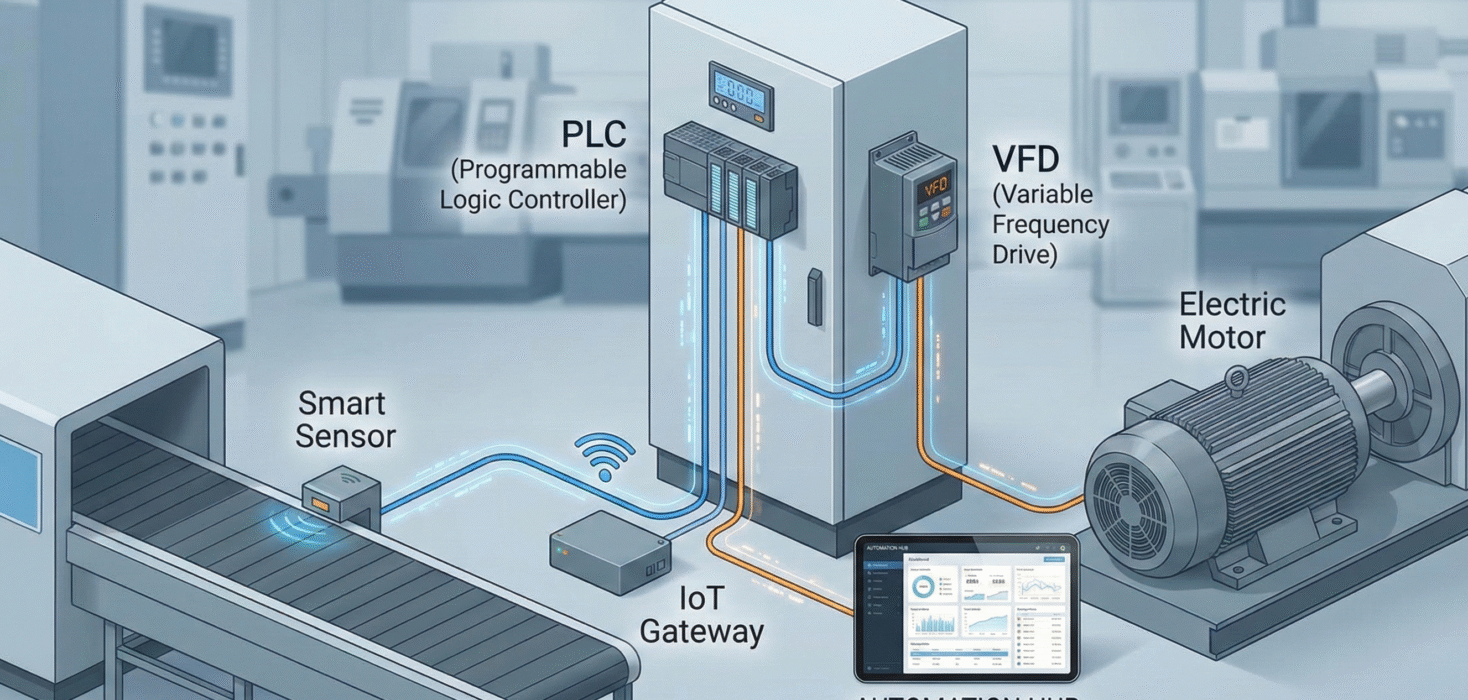

How PLCs, VFDs, and Smart Components Work Together

The real power of modern industrial automation lies in the integration of PLCs, VFDs, and smart electrical components.

- PLCs act as the central controller, making decisions based on input data.

- VFDs regulate motor speed and performance according to the PLC commands.

- Smart components provide continuous feedback, ensuring systems operate efficiently and safely.

For example, in an automated packaging line, a PLC monitors sensors and triggers VFDs to adjust motor speeds. Smart sensors detect product placement errors and communicate with the PLC to prevent jams or defects. This synergy reduces waste, improves quality, and increases operational efficiency.

Benefits of Using Nexa Automation Products

Nexa Automation offers a wide range of PLCs, VFDs, and smart electrical components designed for modern industrial requirements. Some of the major benefits include:

- High Reliability: Industrial-grade products that perform under harsh conditions.

- Energy Optimization: Components designed to minimize power consumption without compromising efficiency.

- Ease of Integration: Compatible with existing systems and scalable for future upgrades.

- Technical Support: Nexa Automation provides expert assistance for seamless implementation.

By choosing Nexa Automation, industries can confidently move towards automation, knowing their equipment is reliable, efficient, and future-ready.

Common Applications

PLCs, VFDs, and smart electrical components find applications across a variety of industries:

- Manufacturing: Automated assembly lines, packaging, and robotic arms.

- Water and Waste Management: Pumps, filtration systems, and treatment plants.

- Energy Sector: Solar plants, wind turbines, and energy distribution systems.

- Food & Beverage: Production, bottling, and refrigeration control.

- Oil & Gas: Pipeline monitoring, drilling automation, and safety systems.

Each of these applications benefits from reduced operational costs, higher accuracy, and safer working environments.

Tips for Selecting the Right Components

Choosing the correct PLC, VFD, or smart component is crucial for maximizing automation benefits. Consider these factors:

- Load Requirements: Assess motor sizes, production capacity, and system demands.

- Compatibility: Ensure the device works seamlessly with existing machinery.

- Environmental Conditions: Select components resistant to heat, dust, and humidity.

- Scalability: Choose devices that can be upgraded as operations expand.

- Technical Support: Prefer brands with reliable support and documentation, like Nexa Automation.

Future Trends in Industrial Automation

The industrial automation sector is evolving rapidly. Some emerging trends include:

- IoT Integration: More devices are becoming interconnected for real-time data analysis.

- AI & Machine Learning: Predictive maintenance and process optimization using AI algorithms.

- Edge Computing: Localized data processing for faster decision-making.

- Sustainable Automation: Energy-efficient solutions reducing carbon footprint.

By adopting these technologies, industries can stay competitive and achieve long-term operational excellence.

Conclusion

Understanding PLCs, VFDs, and smart electrical components is essential for any modern industry looking to optimize productivity, reduce costs, and ensure safety. These components, when integrated, provide unmatched efficiency and reliability. Choosing trusted brands like Nexa Automation ensures your factory is equipped with high-quality, scalable, and future-ready solutions.

Investing in these advanced automation systems is not just about upgrading equipment—it’s about transforming your industrial operations to meet the demands of today and tomorrow. With the right components, proper integration, and continuous monitoring, your factory can achieve seamless automation, operational efficiency, and long-term sustainability.