Industrial automation in 2025 looks very different from what factories and production lines saw a decade ago. Smart machines, connected devices, real-time monitoring, energy-efficient systems, and predictive maintenance are no longer futuristic—they are basic expectations. With this shift, many engineers, technicians, and plant managers wonder whether traditional relay control systems still make sense or if Programmable Logic Controllers (PLCs) have become the outright winner.

Both PLC and relay control play important roles in electrical automation. Yet the decision is not always simple. Budgets, system complexity, maintenance style, safety standards, and scalability all influence which approach works best. As companies aim for faster production, lower costs, and digital transformation, the question becomes even more interesting: PLC vs Relay Control what truly makes sense in 2025?

This article takes an in-depth look at how these two control methods compare today, why they matter, and how industries are shifting toward smarter solutions. With insights aligned to 2025 manufacturing trends and the experience of automation experts like NEXA AUTOMATION, this guide helps you decide what fits your needs without unnecessary jargon.

Understanding What Relay Control Really Does in Modern Automation

Relays have been around for more than a century, and their design hasn’t changed much. A relay is simply an electrically operated switch. When a coil is energized, it triggers contacts that open or close circuits. Because of their simplicity, relays became the foundation of early industrial control panels.

Even in 2025, relays are found almost everywhere—motor starters, lighting panels, small machines, protection circuits, and basic on/off automation tasks. Their biggest strengths still include:

- Low cost per component

- High electrical isolation

- Long lifespan under simple loads

- Zero programming needed

- Easy to troubleshoot with basic tools

Relays excel when tasks are straightforward. For example, turning a pump on when a float rises, switching off a heater when a thermostat trips, or controlling a few motors based on limit switches. Many facilities continue using them because technicians are comfortable with wiring-based logic and physical diagrams.

But their weakness becomes clear as soon as complexity increases. Hard-wired logic is rigid. Making even a small change—like adding a timer or integrating a sensor—requires rewiring. Scaling up becomes messy. Panels grow large. Troubleshooting takes more time. Preventive maintenance becomes inconsistent.

When industries push toward smart factories, IIoT, cloud dashboards, and predictive monitoring, relay control reaches its limits. It can still serve small systems, but it struggles with modern expectations.

Why PLCs Became the Standard in Industry 4.0 and Continue to Lead ?

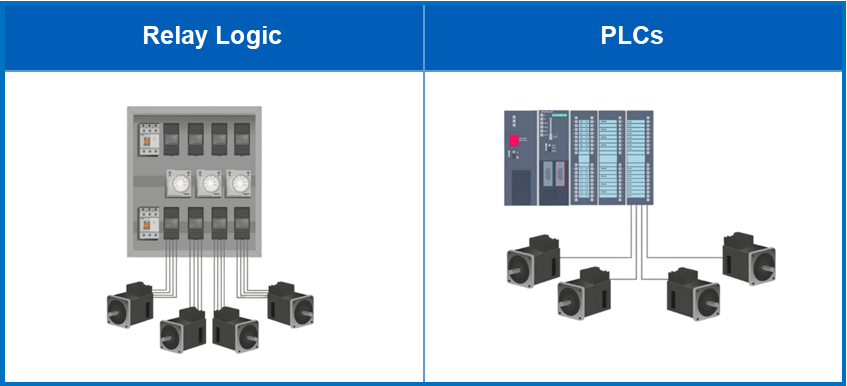

PLCs were invented to replace relay logic. Their design has evolved dramatically, especially in the last five years. Today’s PLCs are compact, powerful, fast, energy-efficient, and fully compatible with digital integration.

A PLC functions like an industrial computer. It reads input data, processes logic based on a program, and sends outputs to control devices. This simple concept makes PLCs incredibly flexible. You can change the logic without touching a single wire.

Modern PLCs used by automation companies like NEXA AUTOMATION include advanced features such as:

- High-speed processors

- Ethernet/IP, Modbus TCP, Profinet, CAN communication

- Built-in HMI interfaces

- Safety modules

- Data logging and remote monitoring

- IIoT and cloud connectivity

- Real-time diagnostics

- Expandable I/O modules

All these features align perfectly with what 2025 factories need—efficiency, scalability, and smart analytics. Another big advantage is standardized programming. Whether you use ladder logic, function block diagrams, structured text, or SFCs, the control logic remains digital and portable.

Even better, PLCs drastically reduce panel size. A complex relay control panel that once required hundreds of relays can now fit into a single compact PLC rack. That saves cost, power, wiring time, and maintenance hours.

2025 Manufacturing Trends That Impact the PLC vs Relay Debate

Automation technology does not exist in a vacuum. Industrial decisions change with global trends, new market demands, and business priorities. The question of PLC vs relay control in 2025 becomes clearer when we consider where the world is heading.

1. Rise of Smart Manufacturing and Digital Tracking

Factories want live data—machine status, energy usage, production counts, quality deviations, and error logs. Relays cannot provide this information, but PLCs can. Modern PLCs even support dashboards on mobile phones, making monitoring easier and more transparent.

2. Predictive Maintenance and Zero-Downtime Goals

Relay failures often go unnoticed until the machine stops working. PLCs, however, can monitor internal health, I/O states, cycle counts, and component behavior. Predictive alerts help avoid machine downtime.

3. Global Push for Energy Efficiency

Relays waste power when coils remain energized. PLC outputs consume far less energy because their internal switching circuits are optimized. Over months or years of 24/7 operation, this difference becomes meaningful.

4. Workforce Skills and Training Trends

Younger technicians entering the industry learn automation through PLCs, not relay logic. Educational institutions now prioritize PLC programming, HMI development, and SCADA integration. Relay skills still matter, but PLC expertise is becoming the default.

5. Integration With ERP, MES, SCADA, and IoT Platforms

Relays cannot communicate with digital platforms. PLCs easily connect with:

- SCADA systems

- MES software

- ERP and production planning

- Cloud-based analytics

As businesses move toward unified digital control, PLCs naturally fit better.

Where Relay Control Still Makes Sense?

Despite rapid modernization, relays are far from obsolete. They continue to shine in specific situations where simplicity matters more than intelligence.

For example, many food processing units, textile machines, water pumps, HVAC systems, agricultural equipment, and small workshops still prefer relay control because:

- The initial cost is very low.

- The machine performs only basic switching.

- Operators need fully manual control.

- Environments require simple maintenance without programming.

Relays are also excellent for interlocking, power switching, and safety circuits where mechanical separation is beneficial. Many PLC-based panels still include relays for isolating loads and managing high-current devices.

Where PLCs Clearly Outperform Relays?

Even small machines today often require more than basic logic. Once the need for timing, counting, sequencing, analog control, or safety logic arises, PLCs win instantly.

Industries adopting PLCs in 2025 include:

- Automotive assembly

- Pharmaceuticals

- Food and beverage plants

- Packaging machines

- Oil and gas

- Wastewater management

- Smart warehouses

- Renewable energy systems

- Robotics and motion control

PLCs also prove invaluable when a business wants to expand later. Adding new features becomes as simple as updating a program and adding I/O modules.

Cost Analysis: The 2025 Perspective

Many people assume PLCs are more expensive than relays. This used to be true, but technology has changed the picture.

Relay System Costs Include:

- Hardware wiring

- Hundreds of relays for medium complexity

- Manpower for installation

- Extra panel space

- Troubleshooting time

- Long-term maintenance

PLC System Costs Include:

- Controller

- I/O modules

- Programming

- Occasional software updates

In 2025, PLC prices have become competitive. When you calculate installation hours, wiring reduction, increased safety, and future flexibility, PLCs often become more cost-effective—even for smaller systems. Automation companies like NEXA AUTOMATION help industries balance cost and performance by selecting PLC models suited to the specific application.

Scalability and Flexibility: A Deciding Factor

In fast-growing industries, scalability is everything. Production targets change every few months. New machines are added. Processes expand. Quality checks become stricter. Relay systems collapse under such pressure because they are not designed for flexibility.

If you need to add:

- new sensor inputs

- new motors

- new alarms

- communication modules

- tracking features

- remote monitoring

you cannot modify relay logic without major rewiring. It costs time and money.

PLCs provide a future-ready foundation. With modular hardware and programmable software, growth becomes smooth. You can add new logic in minutes. This alone makes PLCs the better long-term investment.

Speed, Safety, and Reliability—Key Metrics for 2025 Machines

Speed

PLCs react in microseconds. Relay contacts take milliseconds, and repeated switching wears them out. When your application requires precision timing, PLCs offer unmatched accuracy.

Safety

Modern PLCs include safety I/O, emergency stop handling, fault detection, and error logs. Relay systems depend heavily on manual oversight, which increases risk.

Reliability

Relays face issues such as:

- contact wear

- coil heating

- mechanical sticking

PLCs do not suffer from these mechanical limitations. Their solid-state circuits offer high consistency.

Ease of Maintenance and Troubleshooting

Relay panels often become “spaghetti wiring” during expansion. Finding a single failed relay in a large circuit can take hours. Replacement becomes tricky when documentation is outdated.

PLCs simplify this entire process.

With HMI screens, fault messages, and system logs, maintenance teams know exactly what went wrong. This reduces downtime and eliminates guesswork. Brands like NEXA AUTOMATION often integrate smart diagnostics into PLC-based installations, making maintenance faster and safer.

Programming Trends in 2025 and How They Affect the Choic

PLC programming languages such as Ladder Logic and Function Block Diagram have become industry standards. Their graphical interface makes them easy to understand, even for technicians familiar with relays.

In 2025, programming has taken another leap:

- Cloud-based PLC programming

- Web server interfaces

- AI-assisted debugging

- Remote firmware updates

- Standardized communication protocols

Relay control simply cannot enter this ecosystem. If your automation system might one day integrate with digital platforms, PLCs are the safer choice.

Environmental and Energy Considerations in the 2025 Industry

Sustainability is one of the biggest global priorities. Manufacturing units aim to reduce energy waste, heat generation, and material usage.

Relays consume constant coil energy, generate heat, and require more wiring materials. In contrast, PLCs consume minimal power and create less heat. This helps companies meet energy targets and reduces operational cost over time.

Real-World Scenario: When a Factory Shifts From Relay to PLC

Imagine a mid-sized packaging company using a relay-based system for years. The machines work fine, but every time the production team requests a new feature—like an automatic counter, batch logging, or an emergency interlock—the maintenance team faces long hours of rewiring.

After a certain point, the panel becomes congested. Wire tracking becomes confusing. A small fault can stop the entire system, causing downtime and production delays.

Once the company switches to a PLC-based control system installed by NEXA AUTOMATION, the change is noticeable:

- The panel size is reduced drastically.

- Machine logic becomes easier to update.

- Faults show up on HMI screens.

- Production reports generate automatically.

- Safety improves due to better error detection.

- Energy costs drop over time.

This type of transformation is happening in many industries as businesses embrace Industry 4.0 and prepare for Industry 5.0.

Future-Proofing Your Automation System

The biggest reason companies choose PLCs in 2025 is simple: future-proofing.

No one wants to invest in a system that becomes outdated within a year. Relay control, while reliable, is static technology. It cannot evolve. It cannot connect. It cannot communicate.

PLCs, on the other hand, continue to grow with your factory. Manufacturers release new features, security patches, communication modules, and updates that keep your system relevant for years.

Even better, PLCs integrate with AI systems, machine learning algorithms, and predictive analytics platforms—making them essential for the next generation of automation.

So, Which One Should You Choose in 2025?

Relay control is ideal for:

- Very simple on/off logic

- Small machines

- Budget-limited setups

- Manual or semi-automatic systems

- Low-tech environments

PLCs are ideal for:

- Smart automation

- Scalable systems

- Complex logic

- High-speed process control

- Safety-critical applications

- Data-driven industries

- IIoT and cloud connectivity

- Companies preparing for future expansion

Automation experts at NEXA AUTOMATION often advise businesses to assess long-term goals, not just immediate cost. If the system may grow, expand, or require digital integration later, a PLC offers far more value.

Relay controls are still useful, but in 2025, PLCs have become the default choice for most automation needs—especially for businesses seeking efficiency, transparency, and modern control.