TopTeng

Showing all 43 results

-

ABB AC800M Industrial Automation Controller

Quick ViewThe ABB AC800M Industrial Automation Controller is a modular, high‑performance process control and PLC system designed for reliable, scalable automation in complex industrial environments. It supports advanced control loops, redundancy, and seamless integration with drives and third‑party devices.

keywords: ABB AC800M, Industrial Automation Controller, Programmable Logic Controller, Process Control System, Modular PLC, Redundant Controller, High Availability Controller, IEC 61131‑3 Support

-

ABB DSQC Series Robot Control & Teach Pendant Modules

Quick ViewThe ABB DSQC Series comprises advanced robot control and teach pendant modules designed for seamless interaction, precise programming, and reliable operation with ABB industrial robot systems such as IRC5 and earlier generations. These modules offer intuitive interfaces, ergonomic design, and robust performance for automation applications.

keywords: ABB DSQC Series, Robot Teach Pendant, Robot Control Module, ABB Robot Interface, FlexPendant, Industrial Robot Controller, Robot Programming Interface

-

ABE040

Quick View» 19″ system rack with a standard height of 6U

» Robust aluminium construction

» Modular concept allows specific cards to be added for machinery protection and / or condition

monitoring

» Cabinet or panel mounting

» Backplane supporting the VME bus, the system’s raw signal, tacho and open collector

(OC) buses, and power supply distribution» Power supply check relayThe system racks are used to house hardware for the series of machinery protection systems and condition monitoring systems, from product line.

-

CA134 piezoelectric accelerometer

Quick ViewDesigned for the long-term measurement of vibration over wide temperature ranges in extreme environments, such as gas turbines or cryogenic applications

- Operating temperature: −54 to 500 °C, −253 (20 K) to 500 °C for cryogenic version

- Frequency response: 0.5 to 6000 Hz

- Available as a sensor only (no integral cable) or with an integral mineral-insulated (MI) with a double braid

- Certified for use in potentially explosive atmospheres

-

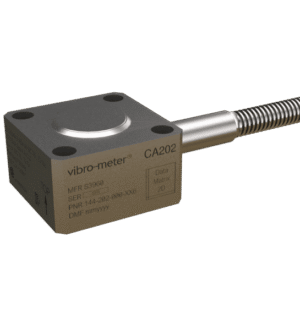

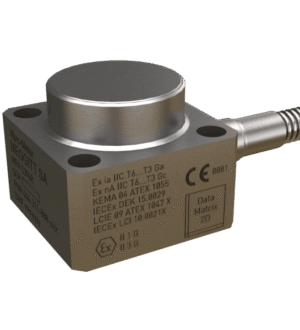

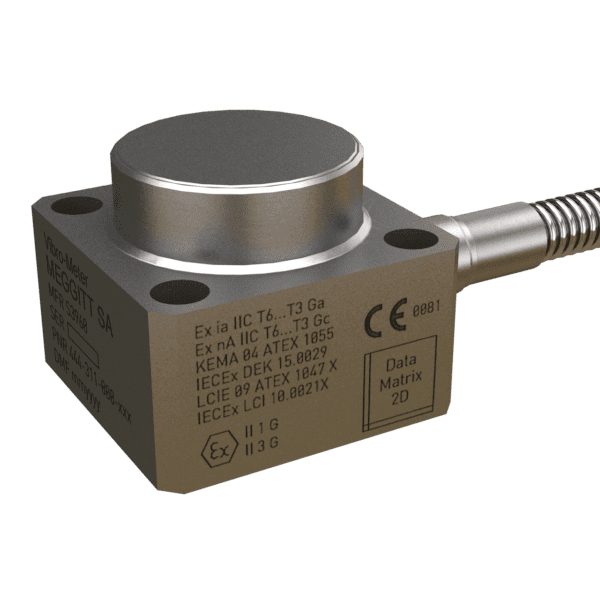

CA202 piezoelectric accelerometer

Quick ViewDesigned for the long-term measurement of vibration in extreme environments, such as heavy-duty gas turbine and steam turbine

- Operating temperature: −55 to 260 °C

- Frequency response: 0.5 to 6000 Hz

- Available with an integral soft-line cable with a flexible stainless steel hose

- Certified for use in potentially explosive atmospheres

-

CA901 piezoelectric accelerometer

Quick ViewDesigned for the long-term measurement of vibration in extreme environments, such as gas turbines and nuclear applications

- Operating temperature: −196 to 700 °C

- Frequency response: 3 to 3700 Hz

- Available with an integral mineral-insulated (MI) cable

- Certified for use in potentially explosive atmospheres

-

CE134 piezoelectric accelerometer

Quick View- Designed for the long-term measurement of vibration in severe environments, such as gas turbines and compressors

- Wide temperature range: −55 to 350 °C

- High frequency response: up to 10000 Hz

- Current output (5 µA/g) for signal transmission over long distances: up to 1000 m

- Certified for use in potentially explosive atmospheres

-

CE281 piezoelectric accelerometer

Quick View- Designed for the long-term measurement of vibration in severe environments, such as gearboxes, compressors, pumps and fans

- Wide temperature range: −55 to 260 °C

- High frequency response: up to 7000 Hz

- Current output (10 µA/g) for signal transmission over long distances: up to 1000 m

- Certified for use in potentially explosive atmospheres

-

CE311 piezoelectric accelerometer

Quick View- Designed for the long-term measurement of vibration in severe environments, such as heavy-duty gas turbines and steam turbines

- High frequency response: up to 8000 Hz

- High sensitivity: 50 µA/g

- Current output (50 µA/g) for signal transmission over long distances: up to 1000 m

- Certified for use in potentially explosive atmospheres

-

CP104

Quick ViewCP104 is designed with 3 mounting holes. It is for long-term monitoring or development testing. CP104 pressure transducer may be operated with either softline or hardline cables depending on the required temperature. It can be mounted on various parts of the machine where enclosed pressure can be measured (hydraulic block, combustion chamber, etc.).

-

EA401

Quick View- Very high-quality, reliable extension cable for TQ401 proximity measurement systems

- 50 Ω coaxial cable with FEP insulation (Ø 2.65 or 3.6 mm)

- 1-core, with shield

- Self-locking miniature coaxial connector (female) to self-locking miniature coaxial connector (male)

- Certified for use in potentially explosive atmospheres

-

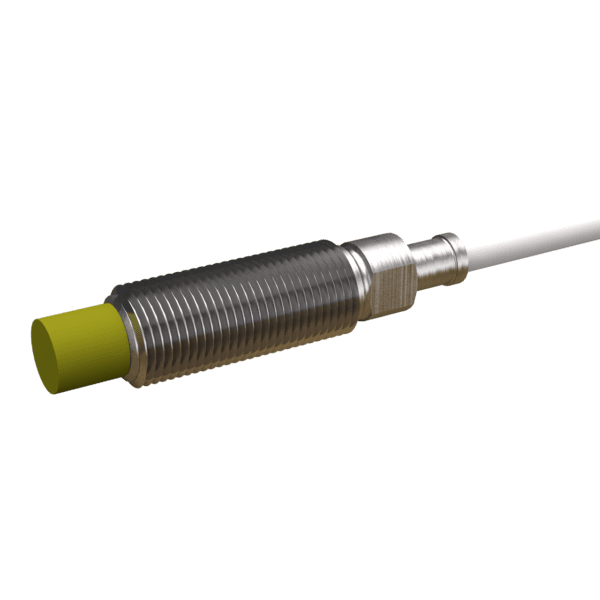

EA402

Quick ViewThe system is based around a TQ403 non-contact sensor and an IQS900 signal conditioner. Together, these form a calibrated proximity measurement system in which each component is interchangeable. The system outputs a voltage or a current proportional to the distance between the transducer tip and the target, such as a machine shaft.

The active part of the transducer is a coil of wire that is moulded inside the tip of the device, made of (polyamide-imide). The transducer body is made of stainless steel. The target material must, in all cases, be metallic.

The transducer body is available only with metric thread. The TQ403 has an integral coaxial cable, terminated with a self-locking miniature coaxial connector. Various cable lengths (integral and extension) can be ordered.

-

EA902

Quick View- Very high-quality, reliable extension cable for TQ9x2 proximity measurement chains

- 70 Ω coaxial cable with FEP insulation (Ø3.6 mm)

- 1-core, with shield

- Self-locking miniature coaxial connector (female) to self-locking miniature coaxial connector (male)

- Versions certified for use in potentially explosive atmospheres

- Conforms to API 670 5th edition

-

IOC4T

Quick View• From • Signal interface card with 4 dynamic signal inputs and 2 tachometer (speed) inputs, for the MPC4 machinery protection card

• Screw-terminal connectors (48 terminals) for all input/output connections

• Contains 4 relays which can be attributed to alarm signals, under software control

• 32 fully-programmable open-collector outputs (jumper selectable) to IRC4 and RLC16 relay cards

• Buffered “raw” sensor signals and analog output signals (voltage or current) for vibration channels

• EMI protection for all inputs and outputs • Live insertion and removal of cards (hot-swappable)

• Available in “standard” and “separate circuits” versions -

IQS450

Quick Viewhe system is based around a TQ423 non-contact sensor and an IQS450 signal conditioner. Together, these form a calibrated proximity measurement system in which each component is interchangeable. The system outputs a voltage or a current proportional to the distance between the transducer tip and the target, such as a machine shaft.

The TQ423 is specially designed for high-pressure applications, with the transducer tip withstanding pressures of up to 100 bar. This makes them particularly suitable for measuring relative displacement or vibration on submerged pumps and various types of hydraulic turbines (for example, Kaplan and Francis). This transducer is also suitable for use when the region of the output of the transducer is cluttered.

-

IQS450

Quick ViewThe system is based around a TQ423 non-contact sensor and an IQS450 signal conditioner. Together, these form a calibrated proximity measurement system in which each component is interchangeable. The system outputs a voltage or a current proportional to the distance between the transducer tip and the target, such as a machine shaft.

The TQ423 is specially designed for high-pressure applications, with the transducer tip withstanding pressures of up to 100 bar. This makes them particularly suitable for measuring relative displacement or vibration on submerged pumps and various types of hydraulic turbines (for example, Kaplan and Francis). This transducer is also suitable for use when the region of the output of the transducer is cluttered.

-

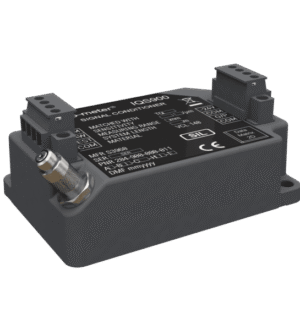

IQS900

Quick View- Signal conditioning for TQ proximity sensors.

- Shaft relative vibration and gap/position measurement for machinery protection and/or advanced condition monitoring.

- Very wide frequency range (DC to 20000 Hz), with configurable sensitivity and measurement range.

- Current output for long-distance signal transmission or voltage output for medium-distance signal transmission.

- Certified for use in potentially explosive atmospheres (Ex) and/or safety-related applications (SIL).

- Fully compliant with API 670 5th edition.

-

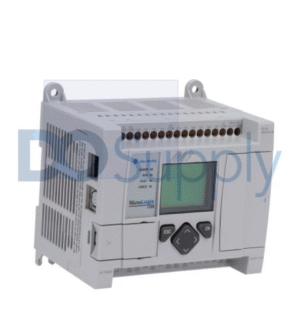

MicroLogix 1763

Quick Viewhe Allen-Bradley 1763-L16BBB is a MicroLogix 1100 Controller. This controller is powered by an external supply voltage of 24VDC with built-in Twelve (12) 24VDC discrete inputs, Two (2) 0-10 VDC analog inputs, Two (2) Relay Outputs, and Four (4) FET Outputs. This controller has a built-in RS232 and Ethernet communication interfaces.

-

MicroLogix 1764

Quick ViewThe 1764-24BWA is a MicroLogix 1500 base unit that belongs to the Bulletin 1764 product family. It has a line power voltage requirement of 85-265 VAC, integrated Eight (8) 24VDC sink/source discrete inputs, Four (4) High-Speed inputs and Twelve (12) Relay Outputs. It has integrated RS232 communication ports for device communication.

-

MPC4

Quick ViewThe MPC4 machinery protection card is the central element in the series machinery protection system (MPS). This very versatile card is capable of measuring and monitoring up to four dynamic signal inputs and up to two speed inputs simultaneously.

The dynamic signal inputs are fully programmable and can accept signals representing acceleration, velocity and displacement (proximity), among others. On-board multichannel processing allows measurement of various physical parameters, including relative and absolute vibration, Smax, eccentricity, thrust position, absolute and differential housing expansion, displacement and dynamic pressure.

-

RLC16

Quick View• Relay card with screw-terminal connectors

• 16 relays with change-over contacts

• Relay driver inverter logic (jumper selectable)

• Low contact resistance

• Low capacitance

• High through power

• Live insertion and removal of cards (hot-swappable)

• Conforms to EC standards for EMC

-

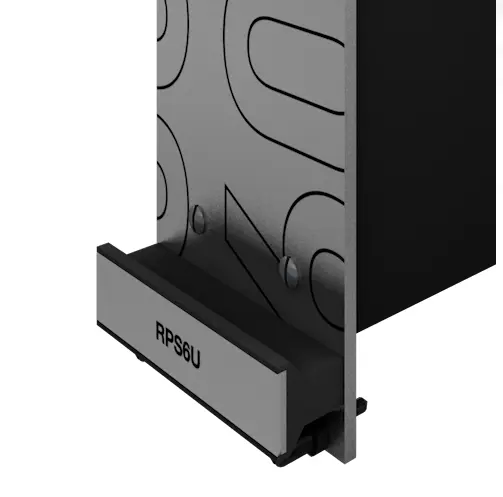

RPS6U

Quick ViewThe RPS6U rack power supplies are designed for use in the series of machinery protection systems and condition and performance monitoring systems.

A RPS6U rack power supply is installed in the front of a ABE04x system rack (19″ system racks with a standard height of 6U) and connects via two high-current connectors to the bus of the rack’s backplane. The RPS6U power supply provides +5 VDC and ±12 VDC to the rack itself and all installed modules (cards) in the rack via the rack’s backplane.

Either one or two RPS6U rack power supplies can be installed in a ABE04x system rack. A rack with one RPS6U power supply (330 W version) supports the power requirements for a full rack of modules (cards) in applications with operating temperatures up to 50°C (122°F).

-

TQ401

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 mm measurement range (Ø5 mm sensor)

- −40 to 180 °C operating temperature, IP68 protection rating

- 0.5, 1.0, 1.5, 2.0 or 5.0 m integral coaxial cable.

- Certified for use in potentially explosive atmospheres

-

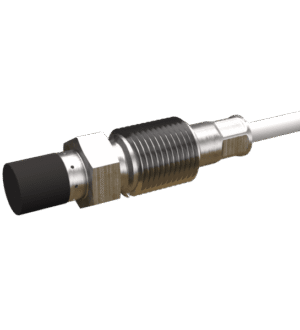

TQ412

Quick ViewThe transducer body is available only with metric thread. The TQ432 version is intended for reversemount applications. Both the TQ422 and the TQ432 have an integral coaxial cable, terminated with a self-locking miniature coaxial connector. Various cable lengths (integral and extension) can be ordered.

The IQS450 signal conditioner contains a highfrequency modulator/demodulator that supplies a driving signal to the transducer. This generates the necessary electromagnetic field used to measure the gap. The conditioner circuitry is made of high-quality components and is mounted in an aluminium extrusion.

-

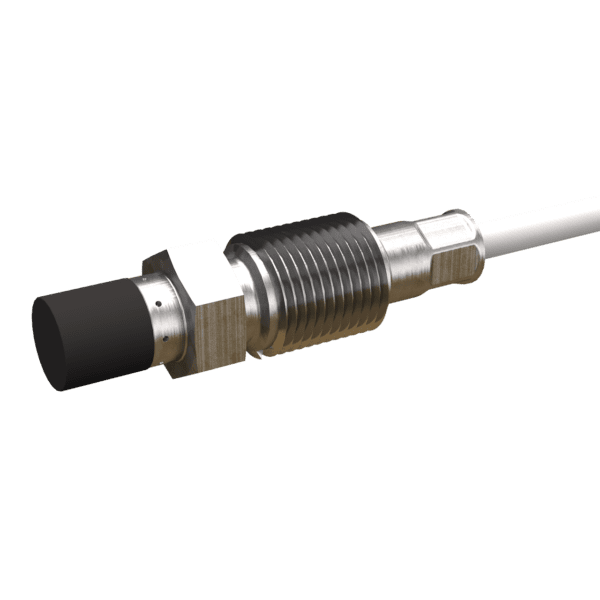

TQ422

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø12.7 mm sensor)

- −25 to 140 °C operating temperature, IP68 protection rating, 100 bar pressure rating

- 1.0, 5.0 or 10.0 m integral coaxial cable

- Certified for use in potentially explosive atmospheres

-

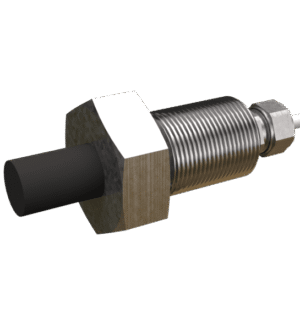

TQ432

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø12.7 mm sensor)

- −25 to 140 °C operating temperature, IP68 protection rating, 100 bar pressure rating

- 1.0, 5.0 or 10.0 m integral coaxial cable

- Certified for use in potentially explosive atmospheres

-

TQ902

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø8.2 mm sensor)

- −40 to 180 °C operating temperature, IP68 protection rating

- 0.5, 1.0, 1.5, 2.0 or 5.0 m integral coaxial cable

- Versions certified for use in potentially explosive atmospheres

- Conforms to API 670 5th edition

-

TQ912

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø8.2 mm sensor)

- −40 to 180 °C operating temperature, IP68 protection rating

- 0.5, 1.0, 1.5, 2.0 or 5.0 m integral coaxial cable.

- Versions certified for use in potentially explosive atmospheres

- Conforms to API 670 5th edition

-

TQ922

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø12.7 mm sensor)

- −25 to 140 °C operating temperature, IP68 protection rating, 100 bar pressure rating

- 0.5, 1.0, 1.5, 2.0 or 5.0 m integral coaxial cable

- Versions certified for use in potentially explosive atmospheres

- Conforms to API 670 5th edition

-

TQ932

Quick View- Designed for the contactless measurement of relative vibration and axial displacement in turbines, compressors, pumps and fans

- 2 or 4 mm measurement range (Ø12.7 mm sensor)

- −25 to 140 °C operating temperature, IP68 protection rating, 100 bar pressure rating

- 0.5, 1.0, 1.5, 2.0 or 5.0 m integral coaxial cable

- Versions certified for use in potentially explosive atmospheres

- Conforms to API 670 5th edition

-

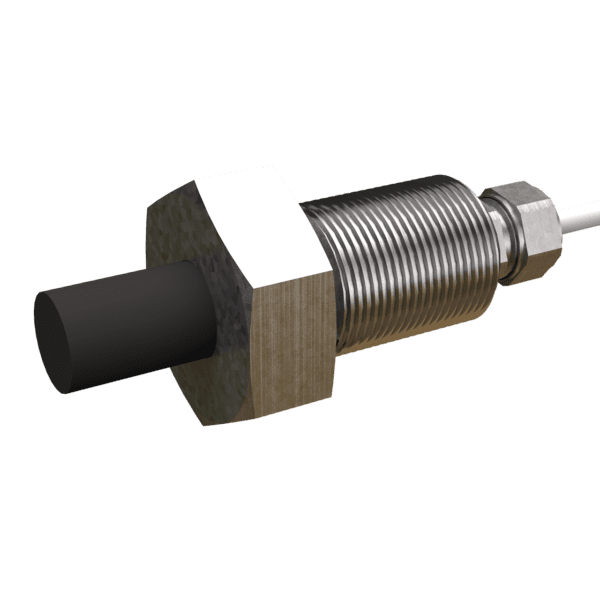

XIO16

Quick ViewThe TQ422/TQ432, EA402 and IQS450 form a proximity measurement system. This proximity measurement system allows contactless measurement of the relative displacement of moving machine elements.

TQ4xx-based proximity measurement systems are particularly suitable for measuring the relative vibration and axial position of rotating machine shafts, such as those found in steam, gas and hydraulic turbines, as well as in alternators, turbocompressors and pumps.

-

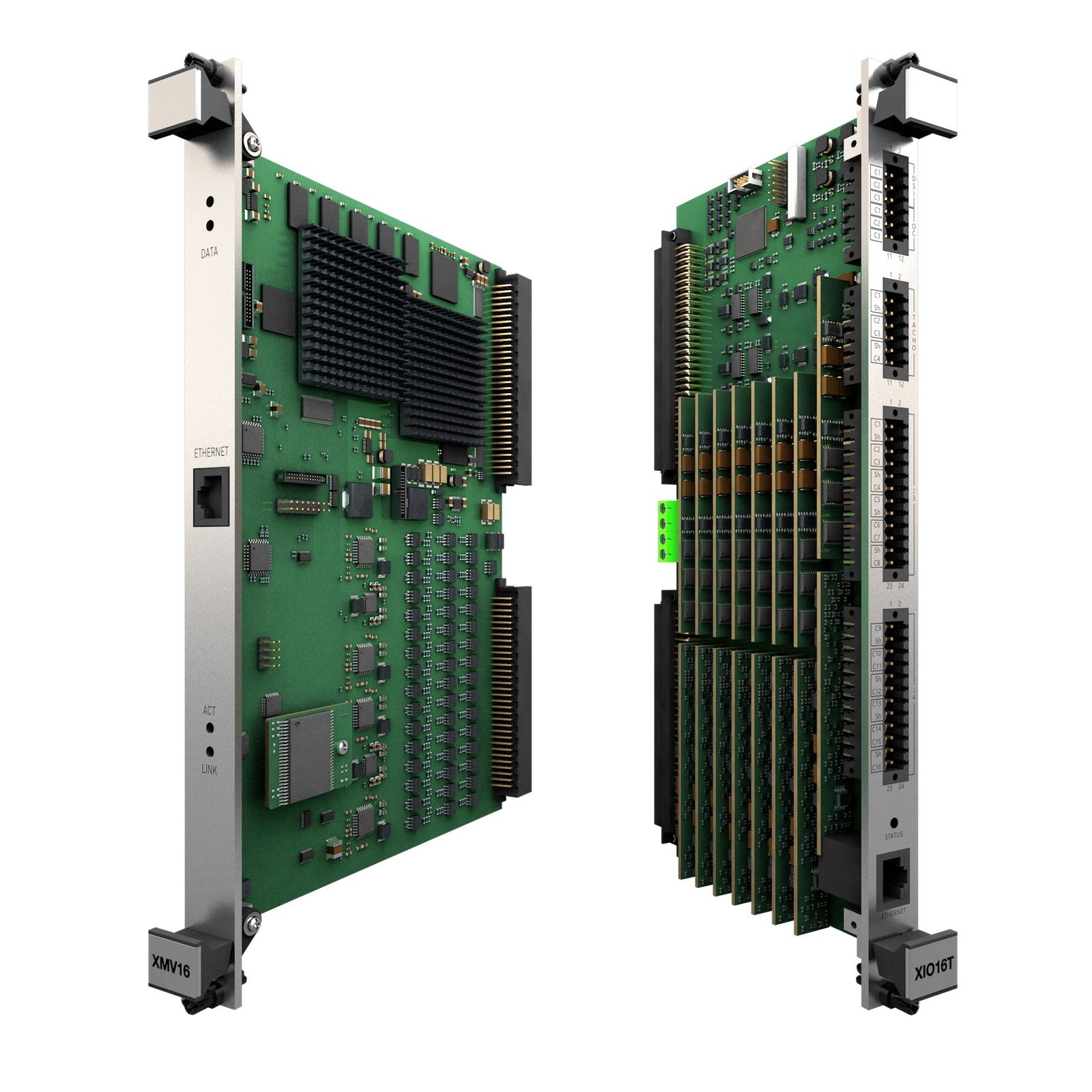

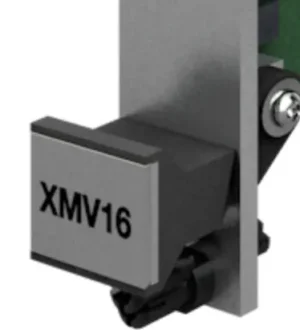

XMV16

Quick View16 dynamic vibration channels and 4 tachometer channels, all individually configurable Simultaneous data acquisition on all channels Up to 20 configurable processed outputs per channel High resolution FFT up to 3200 lines every 1 s Configurable asynchronous and synchronous sampling 24-bit data acquisition and high SNR data processing, with data quality checks 5 configurable severities per processed output and 8 detection levels with hysteresis and time delay Supports signal sharing in VM600 racks EMI protection on all inputs Live insertion and removal of cards (hot-swappable) Direct gigabit Ethernet communication Hardware is fully software configurable